STEEL MANUFACTURING & LOGISTICS

High Impact Steel Manufacturing & Logistics, LLC | Fed Tax ID. 92 - 0430765

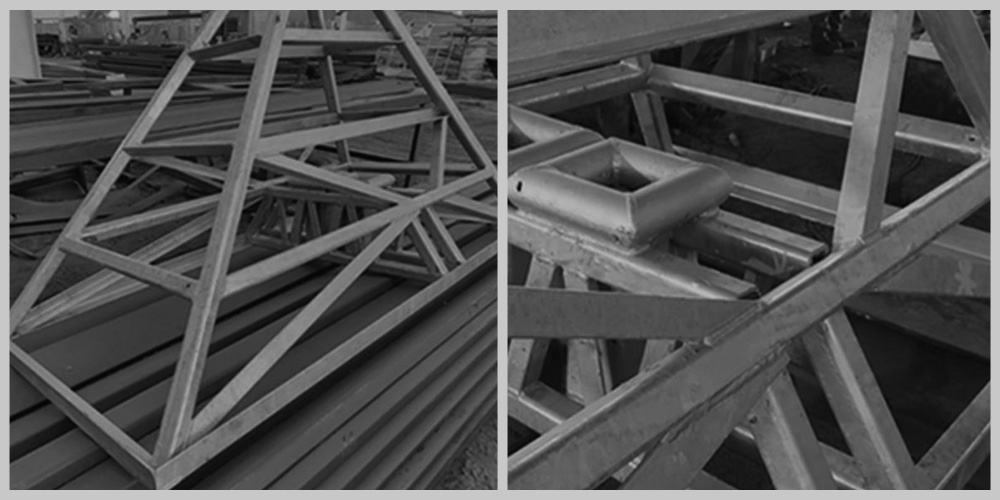

FABRICATION OF STEEL STRUCTURES

Our workshop features a comprehensive selection of cutting, welding, and forming equipment that allows us to fabricate steel components to our customer’s exact specifications.

M A N U F A C T U R I N G S E R V I C E S

STEEL MANUFACTURING & LOGISTIC

STEEL STRUCTURE

High Impact Steel specializes in the design, fabrication, and installation of complete steel structures for industrial, commercial, and institutional projects.

Our team combines field experience with engineering precision to ensure every frame, connection, and weld meets the highest standards of strength and reliability.

From small steel frameworks to large industrial buildings, we manage the entire process, detailing, fabrication and logistics, with full coordination and clear communication.

Capabilities:

- Structural design assistance and shop drawings

- Fabrication of beams, columns, trusses, and bracing systems

- Quality assurance and inspection throughout all phases

Where it helps:

Industrial warehouses, commercial buildings, mezzanines, equipment platforms, and custom structural systems.

We adapt our resources to each project’s requirements, delivering safe, efficient, and long-lasting steel structures built to perform.

HOT-DIP GALVANIZING

High Impact Steel offers hot-dip galvanizing and protective coatings that extend the life of structural and fabricated steel components.

Our process creates a durable zinc layer that bonds metallurgically to the base steel, providing a complete shield against corrosion, impact, and abrasion. We manage every stage — from chemical cleaning and fluxing to dipping and inspection — ensuring consistent, high-quality results.

Capabilities:

- Hot-dip galvanizing at 450°C (840°F)

- Chemical cleaning and surface preparation

- Flux treatment for optimal zinc adhesion

- Formation of multi-layer zinc-steel alloys for maximum durability

- Industrial-grade coating and inspection processes

Where it helps:

Outdoor structures, industrial platforms, handrails, equipment frames, exposed assemblies, and any steel components requiring long-term corrosion protection.

We coordinate galvanizing schedules directly with your project timeline to ensure smooth, on-time delivery.

LATHE MACHINING

Precision machining for custom components and replacement parts.

Our team handles both new parts and repair work, ensuring tight tolerances and consistent quality.

Capabilities:

- Manual and CNC lathe turning

- Shaft, sleeve, bushing, and flange production

- Threading, facing, and boring operations

- Repair and re-machining of worn components

- Custom one-offs or repeat production

Where it helps:

Industrial equipment, structural connections, pipe supports, and custom metal assemblies.

We adapt our capacity to your production or maintenance schedule, minimizing downtime and maximizing reliability.

SAND BLASTING

We offer professional sandblasting and surface preparation for steel components prior to painting, coating, or fabrication.

Our process removes rust, mill scale, and contaminants to achieve the proper surface profile for optimal adhesion and durability.

Capabilities:

- Industrial-grade blasting for structural and architectural steel

- Surface prep for painting, powder coating, or galvanizing

- Controlled grit sizes for specified finishes

Where it helps:

Beams, columns, tanks, frames, stairways, and custom fabrications.

Every part leaves our shop clean, prepped, and ready for the next step in your process.

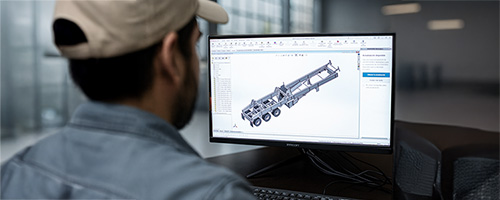

CNC MACHINING

Our CNC machining services deliver precision and repeatability for custom parts, fixtures, and assemblies.

We combine skilled operators with modern equipment to handle complex geometries, tight tolerances, and efficient production runs.

Capabilities:

- Multi-axis CNC milling and drilling

- 3D profiling and pocketing

- Fixtures, jigs, and precision components

- Prototype to large-scale production

- CAD/CAM integration and material traceability

Where it helps:

Structural connections, custom brackets, equipment parts, and detailed metalwork requiring exact tolerances.

We adapt quickly to design changes and urgent needs, keeping your project on track without compromising accuracy.

SHEET METAL

High Impact Steel provides custom sheet metal fabrication for architectural, industrial, and structural applications.

We manage the full process — cutting, forming, welding, and finishing — to deliver ready-to-install components that fit perfectly.

Capabilities:

- Laser cutting, CNC bending, and forming

- TIG/MIG welding and spot welding

- Finishing options: powder coating, galvanizing, polishing

- Prototype to production

- Assembly and packaging for shipment

Where it helps:

Panels, enclosures, guards, ducts, trim, stair components, and architectural details.

Our team can scale production to meet ongoing fabrication needs or one-time custom orders.

LASER CUTTING

High Impact Steel delivers precise laser cutting for industrial, commercial, and architectural components.

Our team combines experienced operators with advanced nesting and QC to produce clean edges, tight fit-ups, and consistent parts—ready for fabrication or direct installation.

Capabilities:

- Precision cutting for carbon steel, stainless, and aluminum

- Clean edges with minimal post-processing

- Smart nesting for material yield and cost control

- Rapid turnaround for prototypes and production runs

- CAD-to-part workflow (DXF/DWG/STEP supported)

Where it helps:

Brackets, gussets, plates, signage, enclosure panels, architectural details, and custom assemblies.

We adapt our capacity to your schedule—rush jobs, phased releases, or large batch production.

POWDER COATING

A durable, uniform finish that stands up to real-world use.

Our powder coating process includes surface prep and quality checks to ensure long-lasting performance on structural and architectural steel.

Capabilities:

- Industrial-grade pretreatment and surface prep

- Wide color range (RAL/standard matches) and textures

- Indoor/outdoor formulations for corrosion resistance

- Masking, plugging, and multi-coat systems

- Integrated QA for color, coverage, and cure

Where it helps:

Handrails, stairs, equipment platforms, guardrails, architectural metals, exterior panels, and custom fabrications.

We align finishing schedules with your project timeline—coordinating directly with fabrication and delivery.

CNC BENDING

High Impact Steel offers precision CNC bending using advanced press-brake systems designed for efficiency, consistency, and accuracy. Our ADH WAD series machines feature servo-driven hydraulic systems that remain idle when not in use, providing significant energy savings without compromising productivity.

This technology allows us to deliver clean, repeatable bends for a wide range of materials and applications — from construction components to automotive parts — ensuring every piece meets exact specifications and tight tolerances.

Capabilities:

- CNC press-brake forming with servo-driven efficiency

- Consistent, high-precision bending for complex geometries

- Multiple bend sequences, hems, and offsets

- Quick setup for prototype or production runs

- Integration with laser cutting and welding processes

Where it helps:

Brackets, panels, enclosures, trims, frames, stair components, and custom metal parts requiring accurate and repeatable forming.

We scale up or down as needed—supporting fast changes, design updates, and phased deliveries.

O U R P R O J E C T S

STEEL MANUFACTURING & LOGISTICS

BUILDING STRONG PARTNERSHIPS ACROSS BORDERS — MEXICO, U.S., AND CANADA

At High Impact, we work closely with contractors and construction companies across the

United States and Canada AS WELL AS MANUFACTURING PLANTS. Our mission is to continuously enhance quality, reduce costs, and optimize delivery timelines.

Supported by a robust infrastructure in Mexico, a flexible production workflow, and a highly skilled team, we tailor every project to meet our clients’ unique needs — ensuring efficiency, precision, and reliability at every stage of production.

MISSION

To be a leading provider of metal fabrication services across the United States, Mexico, and Canada — adding value for our clients through innovation, foresight, and consistent, high-quality performance.

VISION

To be the highest value provider of metal fabrication and supply services with outstanding technical expertise.

CORE VALUES

We work toward our vision and mission and execute projects with integrity, safety and purpose to our clients, co-workers and suppliers, putting the heart on front in everything we do.